Sheet Metal Fabrication

As a leading sheet metal production company based in Southern California, Shear Metal Production specializes in providing high-quality solutions tailored to meet the needs of our value clients. With state-of-the-art equipment, skilled craftsmen, and a commitment to excellence, we offer a wide range of services to bring your projects to life.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of shaping and manipulating metal sheets to create a desired product or component. This process involves various techniques such as cutting, bending, welding, and assembling to transform flat metal sheets into complex and functional components. The type of metal used can vary based on the specific project requirements, with common materials including aluminum, steel, copper, and brass.

Our services include, but not limited to:

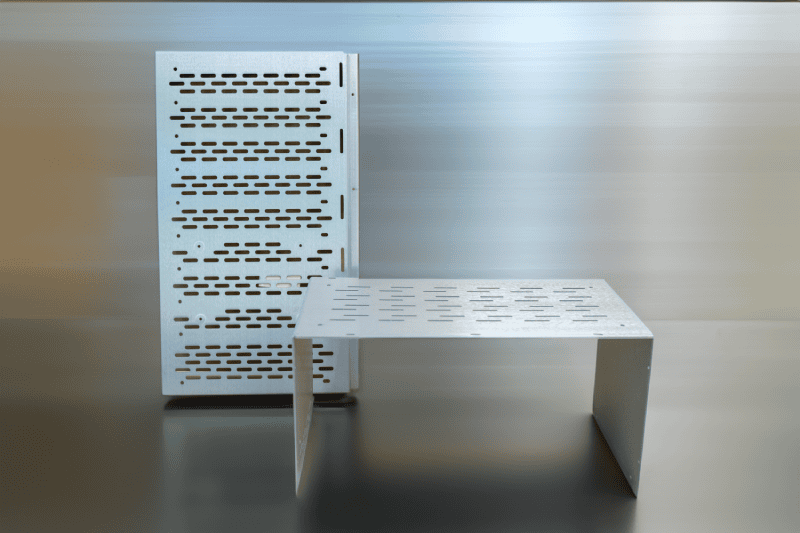

Precision Laser Cutting: Utilizing advanced CNC cutting technology, we can accurately cut sheet metal to your exact specifications, ensuring precise dimensions and clean edges for optimal fit and functionality.

Shearing: Ability to handle various thicknesses and types of sheet metal materials, including steel, aluminum, stainless steel, and copper.

Prototyping: From concept to prototype, we work closely with our clients to develop and refine their designs, offering rapid prototyping services to test functionality and validate designs before moving into full-scale production.

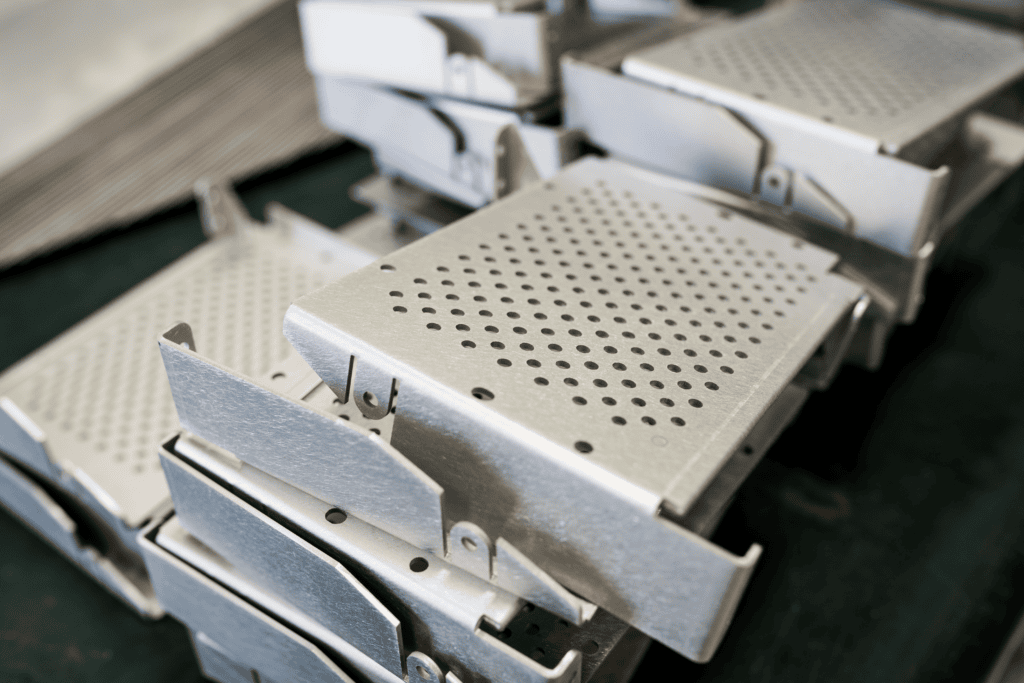

Large-Scale Production: With our extensive capabilities and production capacity, we can handle projects of any size and volume, from small-batch runs to large scale production, delivering consistent quality and efficiency every step of the way.

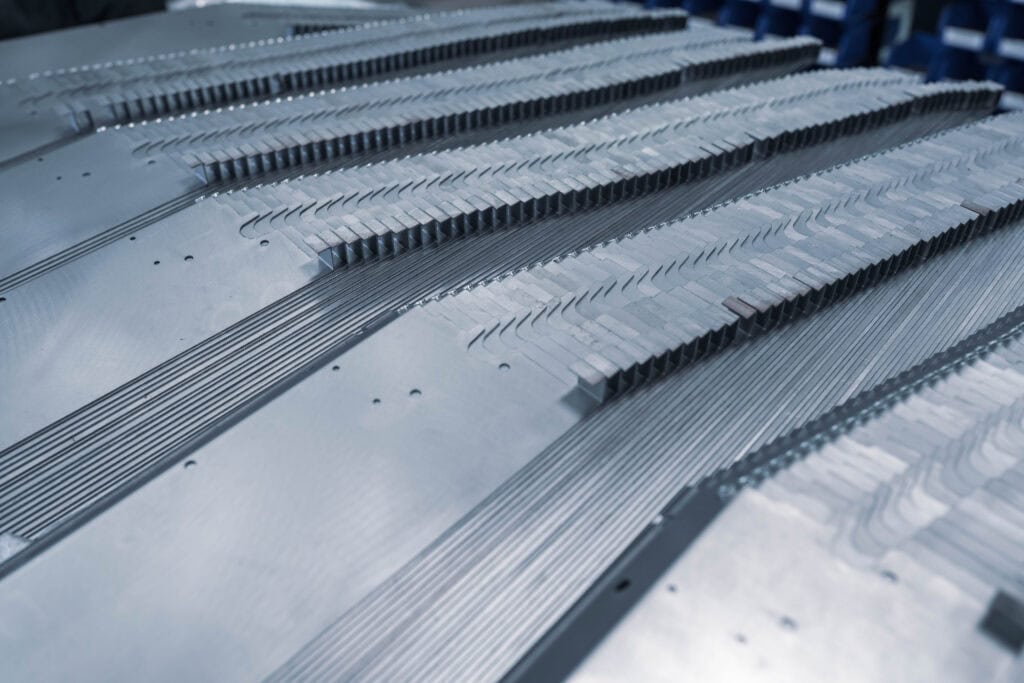

CNC Punching: Utilizing our computer-controlled punching machines, we are able to punch holes or shapes into metal sheets with high precision and speed. This process is perfect for creating complex designs and patterns, making it a cost-effective solution for large-scale productions.

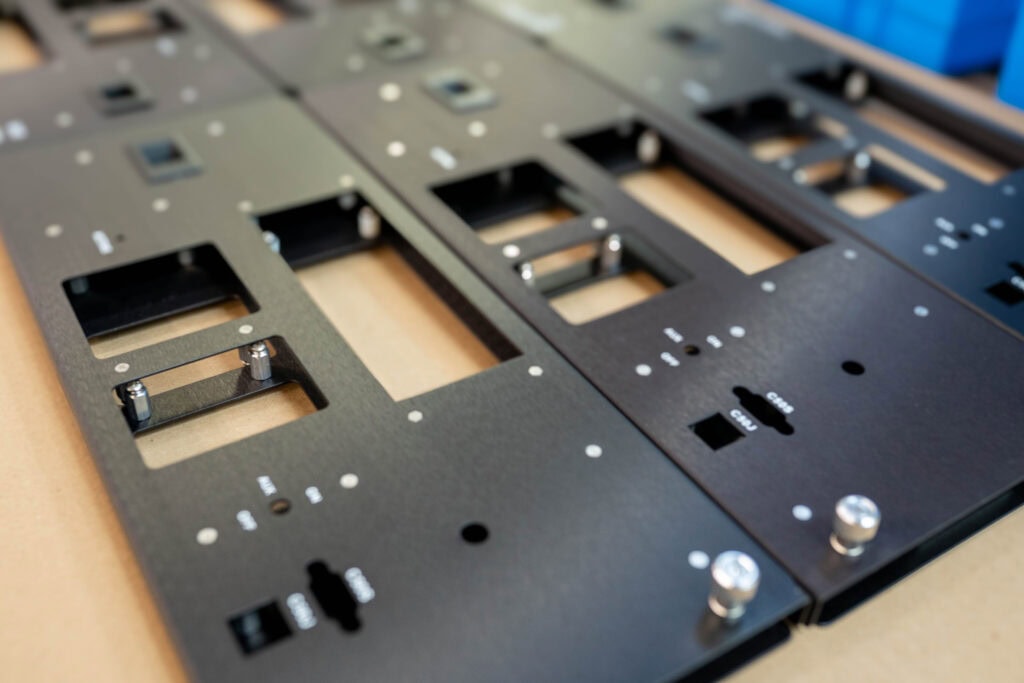

Bending and Forming: Our press brakes and other bending equipment enable us to bend and form metal sheets into various shapes and angles. This process is essential in creating components such as brackets, chassis, enclosures, and more.

Material Souring and Supply Chain Management: Sourcing the appropriate sheet metal materials and managing the supply chain to ensure timely delivery and availability of materials.

Industries We Serve

Our sheet metal fabrication services cater to a wide range of industries, including

- Aerospace/Military

- Electric Vehicle

- Medical

- Construction

- Contract Manufacturers

- Industrial

- Power Related

Why Choose Us?

Been in business since 1988, Skilled, experienced, expert staff will help you find the best solutions to your fabrication needs from prototypes to small or large production runs.